YH20223

Instiker

| Color: | |

|---|---|

| Size: | |

| Material: | |

| Application: | |

| Availability: | |

| Quantity: | |

Product Name: 25μm Transparent PET Acrylic 80g White Glassine

1. Face Stock: Transparent PET

Caliper (μm): 19±5% GB/T 451.3-2003

Weight (g/㎡): 26±5% GB/T 451.2-2002

2. Adhesive Performance: Acrylic

Initial Adhesion (N): 9.88 FTM 9

20 min.180'Peel Adhesion (N/25mm) : 9.39 FTM 1

20 min.90'Peel Adhesion (N/25mm): 8.24 FTM 2

Storage Temperature: -15°C to 80°C

Minimum Lakelling Temperature: 10°C

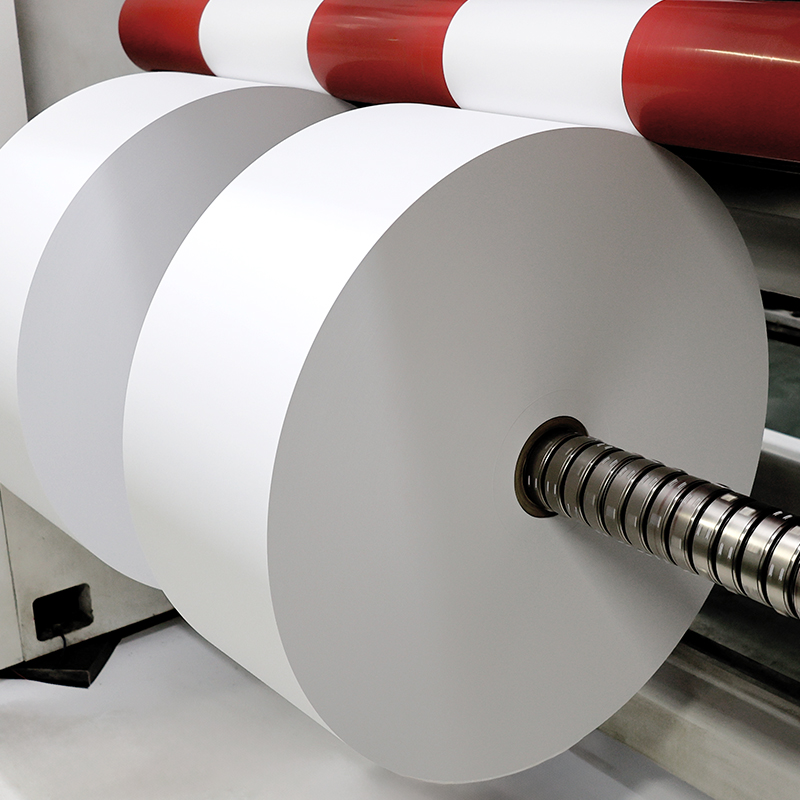

3. Liner: White Glassine

Caliper (μm): 65±5% GB/T 451.3-2003

Weight (g/㎡): 80±5% GB/T 451.3-2003

It can be stored for 1 year at the temperature of 23+2°C and relative humidity of 50+5%

Transparent PET self-adhesive labels are made from PET film as the base material. The surface is treated to enhance transparency and printing compatibility. A pressure-sensitive adhesive layer is coated on the back, and a release liner is laminated on the bottom to form a self-adhesive label material. Through thermal transfer, digital printing, or screen printing methods, images and text can be presented. After being adhered, the surface texture or base color of the object being attached can be clearly displayed.

The light transmittance of the substrate reaches 90% - 95%. After being adhered, it can fully display the surface texture, color or underlying information of the object being attached, without any obvious visual obstruction. It is particularly suitable for "invisible label" scenarios.

*Electronic industry: Transparent shell parameters labels for mobile phones, computers and other electronic products, transparent cover labels for LED lighting fixtures, transparent packaging labels for electronic components, with temperature resistance and anti-static properties suitable for the needs of the electronic industry.

*Medical industry: Transparent medical device shell labels, transparent labels for medicine bottles, environmentally friendly and compliant with regulations, resistant to alcohol disinfection, meeting the hygiene standards of the medical industry.

*Automotive industry: Transparent interior components labels for cars, car stickers, resistant to high and low temperatures, anti-ultraviolet, suitable for both interior and exterior environments of cars.

Q: Is this label fully recyclable?

A: Yes, the synthetic face stock and recycled kraft liner are both recyclable in plastic and paper streams, respectively. Remove adhesive residue before recycling.

Q: Can it be composted?

A: The face stock and adhesive are certified for industrial composting (OK Compost Industrial), breaking down into organic matter within 12 weeks under controlled conditions.

Q: How does it compare to traditional paper labels in wet environments?

A: The synthetic fibers repel water, making it 300% more moisture-resistant than kraft or paper labels, ideal for refrigerated or outdoor applications.

Q: Does the eco-friendly adhesive affect bonding strength?

A: No, the plant-based adhesive matches the performance of traditional acrylic adhesives, with a peel adhesion of 10N/25mm on stainless steel, ensuring reliable substrate bonding.

Product Name: 25μm Transparent PET Acrylic 80g White Glassine

1. Face Stock: Transparent PET

Caliper (μm): 19±5% GB/T 451.3-2003

Weight (g/㎡): 26±5% GB/T 451.2-2002

2. Adhesive Performance: Acrylic

Initial Adhesion (N): 9.88 FTM 9

20 min.180'Peel Adhesion (N/25mm) : 9.39 FTM 1

20 min.90'Peel Adhesion (N/25mm): 8.24 FTM 2

Storage Temperature: -15°C to 80°C

Minimum Lakelling Temperature: 10°C

3. Liner: White Glassine

Caliper (μm): 65±5% GB/T 451.3-2003

Weight (g/㎡): 80±5% GB/T 451.3-2003

It can be stored for 1 year at the temperature of 23+2°C and relative humidity of 50+5%

Transparent PET self-adhesive labels are made from PET film as the base material. The surface is treated to enhance transparency and printing compatibility. A pressure-sensitive adhesive layer is coated on the back, and a release liner is laminated on the bottom to form a self-adhesive label material. Through thermal transfer, digital printing, or screen printing methods, images and text can be presented. After being adhered, the surface texture or base color of the object being attached can be clearly displayed.

The light transmittance of the substrate reaches 90% - 95%. After being adhered, it can fully display the surface texture, color or underlying information of the object being attached, without any obvious visual obstruction. It is particularly suitable for "invisible label" scenarios.

*Electronic industry: Transparent shell parameters labels for mobile phones, computers and other electronic products, transparent cover labels for LED lighting fixtures, transparent packaging labels for electronic components, with temperature resistance and anti-static properties suitable for the needs of the electronic industry.

*Medical industry: Transparent medical device shell labels, transparent labels for medicine bottles, environmentally friendly and compliant with regulations, resistant to alcohol disinfection, meeting the hygiene standards of the medical industry.

*Automotive industry: Transparent interior components labels for cars, car stickers, resistant to high and low temperatures, anti-ultraviolet, suitable for both interior and exterior environments of cars.

Q: Is this label fully recyclable?

A: Yes, the synthetic face stock and recycled kraft liner are both recyclable in plastic and paper streams, respectively. Remove adhesive residue before recycling.

Q: Can it be composted?

A: The face stock and adhesive are certified for industrial composting (OK Compost Industrial), breaking down into organic matter within 12 weeks under controlled conditions.

Q: How does it compare to traditional paper labels in wet environments?

A: The synthetic fibers repel water, making it 300% more moisture-resistant than kraft or paper labels, ideal for refrigerated or outdoor applications.

Q: Does the eco-friendly adhesive affect bonding strength?

A: No, the plant-based adhesive matches the performance of traditional acrylic adhesives, with a peel adhesion of 10N/25mm on stainless steel, ensuring reliable substrate bonding.

Transparent PET (polyethylene terephthalate) is a thermoplastic polyester polymer material obtained through polycondensation reaction of terephthalic acid (PTA) and ethylene glycol (EG). Due to its regular molecular structure and controllable crystallinity, it can be processed into highly transparent films, sheets or products. PET is a linear amorphous polymer. Through the directional stretching process, its transparency and mechanical properties can be further enhanced. It is a widely used transparent polymer material.

Water-based adhesive is a type of adhesive system with water as the dispersion medium, mainly formed by dissolving or dispersing high-molecular polymers (such as acrylate, ethylene-vinyl acetate, polyvinyl alcohol, etc.) and additives (thickeners, crosslinking agents, preservatives, etc.) in water. Unlike solvent-based adhesives (using organic solvents as the medium) and hot melt adhesives (used in the form of heating and melting), water-based adhesives achieve curing through water evaporation or polymer particle coagulation, featuring environmental friendliness and low VOC (volatile organic compounds). They are widely used in packaging, textile, construction and other fields.

The 60g white glassine liner protects the acrylic adhesive during storage and transportation. Its smooth surface allows for easy release of the label, which is essential for efficient application in high - volume production settings.

Transparent PET (polyethylene terephthalate) is a thermoplastic polyester polymer material obtained through polycondensation reaction of terephthalic acid (PTA) and ethylene glycol (EG). Due to its regular molecular structure and controllable crystallinity, it can be processed into highly transparent films, sheets or products. PET is a linear amorphous polymer. Through the directional stretching process, its transparency and mechanical properties can be further enhanced. It is a widely used transparent polymer material.

Water-based adhesive is a type of adhesive system with water as the dispersion medium, mainly formed by dissolving or dispersing high-molecular polymers (such as acrylate, ethylene-vinyl acetate, polyvinyl alcohol, etc.) and additives (thickeners, crosslinking agents, preservatives, etc.) in water. Unlike solvent-based adhesives (using organic solvents as the medium) and hot melt adhesives (used in the form of heating and melting), water-based adhesives achieve curing through water evaporation or polymer particle coagulation, featuring environmental friendliness and low VOC (volatile organic compounds). They are widely used in packaging, textile, construction and other fields.

The 60g white glassine liner protects the acrylic adhesive during storage and transportation. Its smooth surface allows for easy release of the label, which is essential for efficient application in high - volume production settings.

Due to the excellent printing performance of PET stickers, it is suitable for letterpress, screen printing, offset printing, flexographic printing to produce various exquisite labels. It also has good performance for special labels.

Due to the excellent printing performance of PET stickers, it is suitable for letterpress, screen printing, offset printing, flexographic printing to produce various exquisite labels. It also has good performance for special labels.